14 Inch Abrasive Wheels, Cut Off Wheels, Metal Cutting Wheels, Cutting Large Workpieces, 355X3.0X25

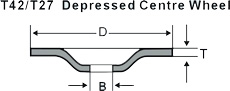

Center flat/Depressed center

14” abrasive cutting discs 355X2.5X25; cutting wheels 355X2.8X25; cut of wheels 355X3.0X25; 9 inches abrasive cut of wheels.

Metal cutting discs, Metal cutting wheels.

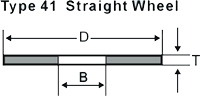

The metal cut off wheels can be in different thickness according to customer’s requirements, this can be made in one single net, two nets, and two and half nets. T41 flat cutting wheels, Mixed high quality brown aluminum oxide and white aluminum oxide. Industrial grade cut off wheels. Durability and sharpness are excellent.

Resin grinding wheel is a widely used grinding tool. It is usually composed of abrasives, adhesives and reinforcing materials. Breaking during operation will not only cause death or serious injury accidents, but also cause serious damage to the workshop or the shell. In order to reduce and control the occurrence of hazards, it is necessary to understand and master the hazards expressed and their preventive measures.

1. Processing and storage

In the process of transportation and handling, if the resin wheel bonded with phenolic resin is wetted, its strength will be reduced; uneven moisture absorption will cause the wheel to lose balance. Therefore, when loading and unloading the grinding wheel, it must be placed carefully and placed in a dry and cool place to maintain the normal state of the grinding wheel.

2. the correct installation

If the resin grinding wheel is installed on an improper instrument, such as at the end of the main shaft of the polishing machine, accidents or breakage may occur. The main shaft should have an appropriate diameter, but not too large, so as to prevent the center hole of the grinding wheel from cracking. The flange should be made of low carbon steel or similar material, and should not be less than one-third of the diameter of the grinding wheel.

3. test speed

The operating speed of the resin grinding wheel shall not exceed the maximum allowable working speed specified by the manufacturer. All grinders should be marked with spindle speed. The maximum allowable peripheral speed and corresponding speed of the resin grinding wheel are also displayed on the grinding wheel. For variable speed grinders and grinding wheels, special protective measures must be taken to allow hand-held grinders to be installed with appropriate allowable speeds.

4. protection measures

The guard should have enough strength to resist the burst of the resin grinding wheel. Some countries have detailed regulations on the design and materials used for protective devices. Generally speaking, cast iron or cast aluminum should be avoided. The grinding operation opening of the guard should be as small as possible and should be equipped with an adjustable baffle.

The above are the protective measures that resin grinding wheels should take. Train the operators many times on the use of specifications and how to judge the quality of the resin grinding wheel to ensure that there will be no dangerous accidents when the workers are operating. Protect workers in all aspects.

Thinner, faster cutting with little burring

Excellent durability

Excellent sharpness

High stability

Cool cut

Highest possible economic value

less material loss

Superior quality with ratio price

Working comfortable and Safety

High performance

355X2.5X25

355X2.8X25

355X3.0X25

cutting of solid material, sections and pipes

OEM is available

Please Feel Free To Ieave Your Needs Here, A Competitive Quotation Will Be Provided According To Your Requirement.