Two nets, two and half nets can be made by customer’s requirements.

Thickness can be customized.

Yuhong as the manufacturer of the abrasive wheels, we have the strictest quality control.

Effect of forming and firing (also known as hardening) process on cutting performance:

1. Forming mainly includes three methods: hot pressing, cold pressing and rolling. The pressure required by hot pressing method is small. High forming density, high hardness and good strength; Hot pressing is widely used in North China; The advantage of cold pressing method is that it does not need the heat source during hot pressing, and is suitable for abrasives with various binders; Cold pressing method is widely used in South China; Rolling method requires less energy, low forming density and low efficiency. Generally, it is used in the flake grinding wheel without reinforcing mesh and export resin wafer grinding wheel.

2.Too low and too high hardening temperature, too short and too long holding time are unfavorable to the cutting performance. The influence of grinding wheel shape and balance on cutting performance:

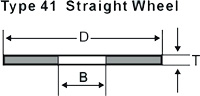

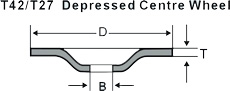

2.1when the thickness is large, the cutting gap is wide and the grinding wheel consumption is large; When the strength is guaranteed, the smaller the thickness, the better, which saves both grinding wheel material and cut material; When the flatness is large, the cutting seam width is determined by the thickest part, while the strength is determined by the thinnest part. During cutting, the wear and vibration are large, which will affect the whole cutting process. When the thickness in the middle of the grinding wheel is large and the thickness on the edge is small, the side of the grinding wheel will grind the cut workpiece during the cutting process. It is “stuck” like a wedge artifact, so the grinding wheel can be made thin in the middle and thick around.

2.2 When the radial runout of the grinding wheel is large, the vibration is large at the initial stage of cutting, which is easy to cause the grinding wheel to fall off, affecting the strength and cutting.

1, smooth cut

2, Safe

3, easy to use

4, quality stability

125X2.0X22.23 T41/T42

125X2.5X22.23 T41/T42

125X3.0X22.23 T41/T42

Applicable to all metal/stainless steel cutting

Can is open

Please Feel Free To Ieave Your Needs Here, A Competitive Quotation Will Be Provided According To Your Requirement.